Guess who's got a 3D Printer!!!

Hey guys!

Blake here again to bring you into the exciting world of additive manufacture with our first foray into 3D Printing! FIRST OFF I have to say that the world of 3D Printing is a confusing, scary, and complicated one. There are experts out there who seem to over complicate things, file types are crazy, and there are so many printers, WHERE TO START?!

So being the excitable person I am, I went with my very first consumer grade 3D printer. But I’m picky as well. When there are terms like FDM, SLA, DLP, SLS, SLM, LOM, and EBM tossed around (I KNOW! SO many acronyms.) But here’s a good place to start for those who want to get into it without too much hassle and nonsense.

The easiest to get into (as there are literally thousands of printers out there including build your own) would be the FDM or Fused Deposition Modeling. This is the most common and abundant extrusion method you will find on the market for many reasons. It’s the cheapest, and fastest. With Fused Deposition there are loads of thermoplastics on spools that print like an inkjet printer, while an inkjet drops dots of ink an FDM printer will drop melted plastics that are funneled through a heating element. You can also find this technology with a smaller maker called the 3Doodler who uses this same technology in a pen form to “Draw in 3d”. With this there are loads of thermoplastics (some of which I went over in my previous blog). It is the only one that can use production grade ones as well. So loads of choice there.

This is the “basics” of an FDM printer

Why wouldn’t everyone use this you ask? While it is great and sometimes really cheap to run, it does lack some finesse of other 3D Printers. The thin layer of plastic binds to the layer beneath, melts and hardens together. So this build up DOES leave lines throughout. Some printers are great at registration and some are a little off. So while iterating is very easy to do and smaller items fairly quick, it does not LOOK the best. You will see the printer lines throughout the piece. In order to get something pretty there are hours of sanding, or “taking it as it is”. FDM is widely for the production end-user goods. We are specifically referring to small, detailed components and technical manufacturing tools. “Some thermoplastics (such as PLA, which is non-toxic) may even be utilized in food and drug packaging, making FDM a favorite 3D printing method within the medical sector”*

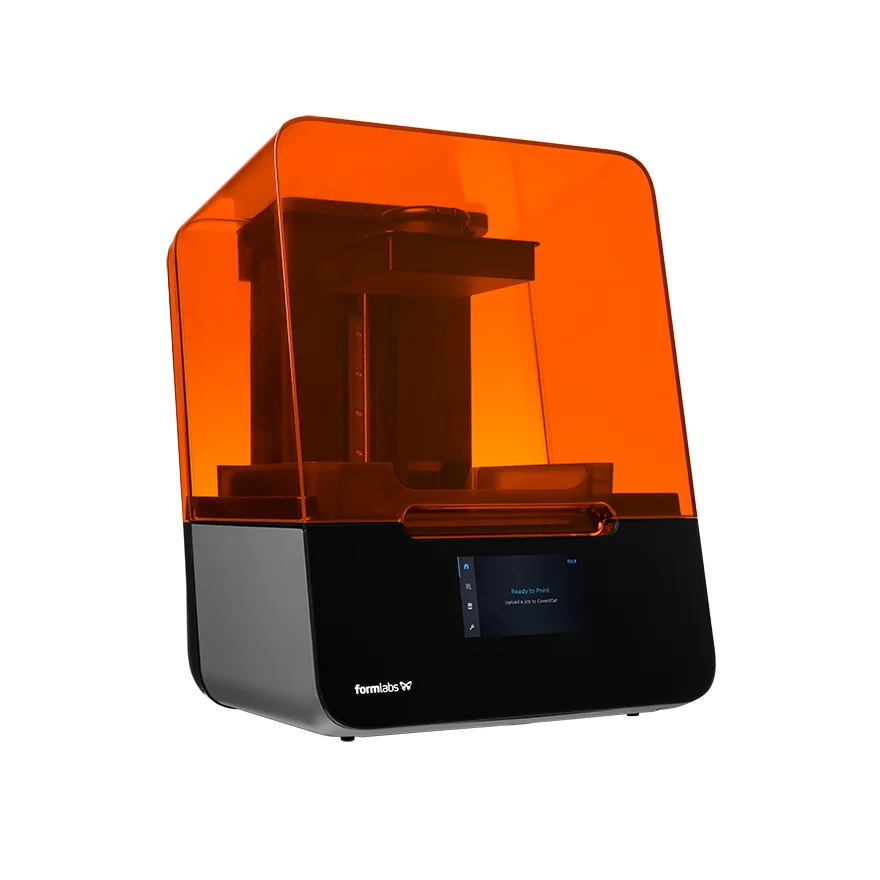

With SLA printing or Stereolithographic printing the machines flash cure resin, or liquid plastics, as the base tray is lifted up and down. This curing hardens in the specific areas that the machine tells it to following the 3d files. After the plastic hardens a stage of the printer drops down in the tank a fraction of a millimeter and laser forms another layer until printing is finished. This takes ‘forever’ but the result is usually more worth it. After all, layers are printed, the item has to be rinsed using a solvent and then put in an ultraviolet oven to complete processing. This method allows for greater resolution and much smoother prints. The best one in my opinion, and from the research I’ve done, is the Formlabs series of printers. They have recently come out with the Form 3. This SLA Printer is a beast. Loads of functions, but somewhat cost prohibitive as the basic package is 3,400.

Formlabs Form 3 pictured.

DLP, or Digital Light Processing is similar to SLA as it using much the same materials but the resin hardens quickly when exposed to a lot of photons, or more simply put, bright light. A layer of hardened material can be produced with this kind of printer in few seconds. After the layer is completed, it is transferred, and printing of the next layer is started.

From the research I have done on these types of printers, the Anycubic Photon Printer and the Epax 3D are both highly reviewed and under $500. After all the research I personally went With the Epax X-1. This printer I chose was based on consumer reviews stating they loved the print resolution, the machine is a work horse (some were describing 500+ prints with the machine with little to no issue). I needed something that would “work right out of the box”. Consumer reviews were saying after a quick leveling it was ready to lock and load. The reviews I went deep on were complaints on the Anycubic that it had some Z wobble. The z-axis of a 3D printer is the vertical axis, so to travel in the z-direction is to move through the layers rather than along them. The Epax had nearly zero issues with this from the reports I had read. Their Build Volumes were nearly the same allowance. So I gave it a shot. :D

Epax and Anycubic

As for the other types of Printers -

Then we get to the fun stuff – the SLS or Selective Laser Sintering. This process uses similar processing as the SLA but with powdered material as opposed to liquid. So you can print loads of different materials, including nylon, glass and ceramics to some metals such as aluminum, silver or steel. Which is pretty cool when you think about all the applications.

SLM, LOM and EBM

“The last three types of 3D printing technologies are Selective laser melting (SLM), Laminated object manufacturing (LOM) and Digital Beam Melting (EBM). Through the last two decades, these technologies have either fallen out of fashion or proved to be economically unviable. As such, you will not find the 3D printers of today using SLM, LOM or EBM technologies.”*

*-.* (https://penandplastic.com/3d-printer-types/)

My first Printer! :D

My first attempt at printing came out ‘ok’. The supports seem to have been “falling out” or not staying together. What it looks like to me is the curing isn’t staying. So I will be adjusting the cure speed on the bottom to 50 to allow more time to cure. This should allow the supports and the other parts to properly cure and not warp when lifting. I have also flipped the print to begin printing at the head. So hopefully these two things should alleviate some of the thickness issues. The slicing program I am using the freeware ChiTuBox.

First Prints

After making some adjustments we ended up with a much better print! It took a few hours more, but that extra bit of cure time worked out well. These are my new settings for the Grey Photopolymer purchased on Amazon.

I have worked out quite a bit of hours to make this work out. And looking at some fun stuff here in the immediate future if this works out. The biggest thing is making sure this longer cure will allow for more detail. After playing with it, ONE figure that I turned upside down worked out well. The other detached almost immediately from the platform. So now I know some of the supports I will have to bulk up and one support is never enough :D

Supports still in tact, two items are missing. Will have see if I need to fish out a load of cured resin :D

OK! SO SUCCESSS!!!! We have a decent first print. There seems to be an error on the mini figure as I had stated before, but I believe this to be a file issue. So we have so far one great print, it’s not 100% like a formlabs or a really expensive printer, but through some more trouble shooting as I go and some settings I Should be able to hone into what I need for this. This is exciting times!

There'‘s a glitch in the base here.

Flattened and lovely figure! :D

As I mentioned this guy fell off the supports and just left a literal pile of resin :D.

Even with the glitch, my little guy looks pretty cool, so I will clean him up and see what I can do with him, printing one more just in case. I want to know it’s 100% a glitch in the file before I keep proceeding. This guy looks pretty good so far though.

I think that’s about it for this update. I will keep posting things on instagram to keep the journey going.

I appreciate your time, and hope this was informative, and as exciting for you as it is for me! Stay tuned for more fun coming soon.